At the beginning, it is worth emphasizing that the engine does not produce “metal filings”, such as during machining. The metal particles that penetrate into the oil are the result of friction between the metal surfaces.

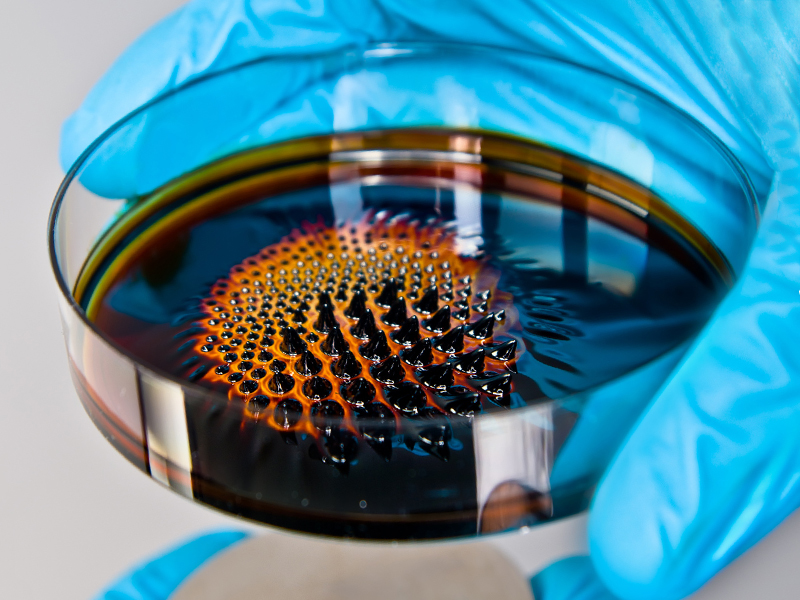

Behavior of oil taken from the engine under the influence of a magnet

Of course, this is a disadvantageous phenomenon and engine designers attach great importance to building an oil main in such a way as to reduce friction of metal elements. However, it is impossible to create an oil film that reduces friction at all points of contact. A typical example is the contact between piston rings and cylinder walls. There are three basic types of rings in reciprocating engines:

– sealing rings (closest to the piston crown), whose task is to maintain high compression and prevent the penetration of exhaust gases resulting from the combustion process into the crankcase, – sealing and scraper rings (middle ring), whose task is to stop the gases that have passed through the sealing ring, and scraping excess oil from the cylinder surface,

– scraper rings (the ring at the bottom) that scrape excess oil from the cylinder liner, leaving a relatively thin film of oil on the cylinder surface.

As can be seen from this calculation, in the upper part of the cylinder, the sealing ring must not come into contact with the oil film, as this is limited by the sealing and scraper rings. This is especially true today, when stricter ecological standards force the combustion of oil particles to be limited. This lack of oil film at the top of the cylinder and the associated greater friction (and greater material abrasion) are clearly evident when disassembling the engine. It is the work without an oil film that causes the widening of the upper part of the cylinder liner in used engines. However, structural reasons are less harmful than negligence in operation. Master-Sport experts advise on what to remember to ensure good lubrication, reduce friction and eliminate the formation of metal particles.

Periodic oil and oil filter changes

With the course of the course, the lubricating properties of the oil decrease and, as a result, it does not ensure the production of an oil film, which is necessary for the proper operation of the contacting elements. Hence, each manufacturer recommends an oil change within a specified period. It is important to change the filter when replacing it. Failure to do so may prevent the new oil from flowing through the unchanged clogged filter, but only through the overflow valve, without cleaning, taking away dirt accumulated on the filter material. This, in turn, can quickly lead to engine damage. It is also worth remembering that the condition for changing the oil is not only the mileage, but also the time of its operation.

Wrong quality of the lubricant

For each engine, the manufacturer recommends the use of oil that meets the relevant standards. Failure to comply with them may result in “breaking” the oil film, that is, loss of lubrication continuity.

Start vigorously with the engine cool

Engine oil in standard engines, after turning off the engine and stopping the oil pump, flows to the oil pan (in sports and off-road cars, the so-called dry sump is used, where the pump sucks oil into the tank). As a result, after starting the engine, the oil pump forces it into the oil main again. Hence, the first moments of driving are always associated with the difficult work of the contacting elements. Therefore, it is important to limit the engine effort until the correct operating temperature of the unit is achieved.

Oil thinning

The lubricating properties of the oil deteriorate significantly when diluted with fuel or coolant. The first case always occurs during a cold engine start-up, when a larger dose of fuel is supplied to the cylinder and its unburned particles flow down the cylinder walls to the oil sump. It is also possible to deliver too high a dose of fuel due to faulty information sent to the engine control unit by a damaged sensor.

The oil is diluted by the coolant as a result of mechanical damage, such as a crack in the head, damage to the gasket under the head, etc.

Oil pump or cooling pump defective

Damage to the oil pump – There is a total or partial reduction of the pressure in the oil main and the lubricant is completely or partially not reaching the sensitive areas. Cooling pump damage – too high engine operating temperature causes individual parts to increase in volume, thus “pushing” the oil film layer and, as a result, they work without proper lubrication. How to reduce improper working conditions and the formation of metal particles? According to specialists from the Master-Sport company, we cannot completely eliminate the formation of metal particles in the engine. However, this phenomenon can be significantly reduced by using the lubricants in the Master-Sport offer, recommended by the manufacturer and replacing them according to the indicated periods / mileages, and by periodically inspecting the lubrication and cooling system. Metal particles formed as a result of normal working conditions are worth absorbing and stopping their flow in the oil. This is what the NeoMag technology, which is used to make Master-Sport filters, is to serve.